PETROLEUM PRODUCT CRUDE OIL.

PETROLEUM PRODUCT.

WHAT IS CRUDE OIL AND WHAT ARE PETROLEUM PRODUCTS?

Crude oil is a mixture of hydrocarbons that formed from plants and animals that lived millions of years ago. Crude oil is a fossil fuel, and it exists in liquid form in underground pools or reservoirs, in tiny spaces within sedimentary rocks, and near the surface in tar (or oil) sands. Petroleum products are fuels made from crude oil and other hydrocarbons contained in natural gas. Petroleum products can also be made from coal, natural gas, and biomass.

PRODUCTS MADE FROM CRUDE OIL

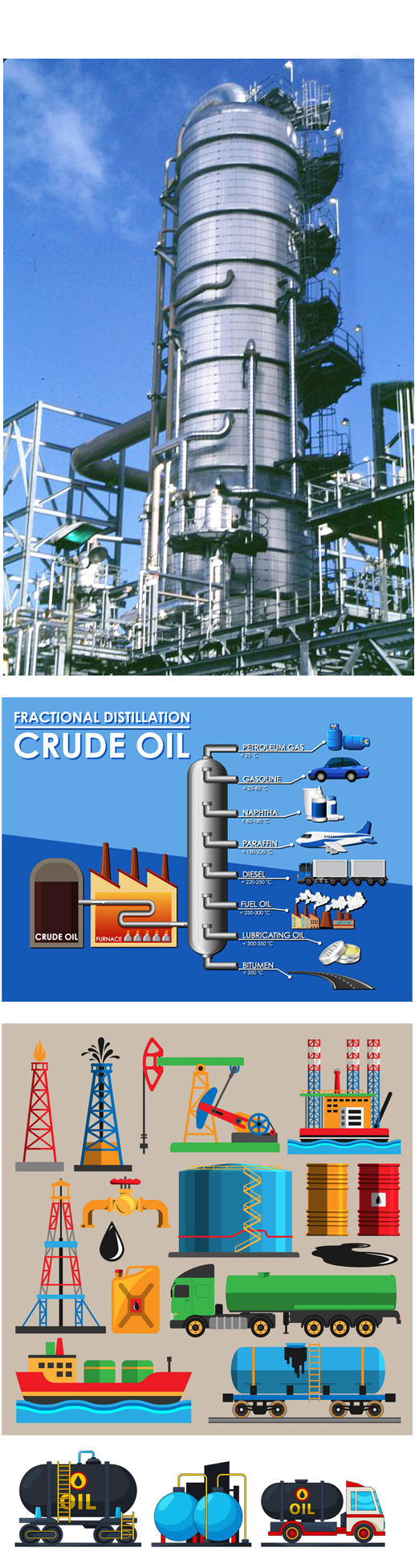

After crude oil is removed from the ground, it is sent to a refinery where different parts of the crude oil are separated into useable petroleum products. These petroleum products include gasoline, distillates such as diesel fuel and heating oil, jet fuel, petrochemical feedstocks, waxes, lubricating oils, and asphalt.

A U.S The Seven Sisters and or OPEC: Solving the mystery of the petroleum market structure 42-gallon barrel of crude oil yields about 45 gallons of petroleum products in U.S. refineries because of refinery processing gain. This increase in volume is similar to what happens to popcorn when it is popped growing up together with them.

CRUDE OIL DISTILLATION PETROLEUM DISTILLATION

Fractional distillation of crude oil is performed in order separate crude oil into its components such as straight run gasoline, diesel, light oil, heavy oil and residue (asphalt, bunker fuel). These distillation fractions are then further processed into familiar petroleum products we recognize like finished gasoline, diesel fuel, lubricating oils and so forth.

Crude oil first goes to an atmospheric distillation column that separates the crude oil components that boil up to 343 C. The portion of the crude oil that boils above 343 C goes on to a vacuum distillation column which fractionates this heavier material in to its components.

THE MACHINERY EQUIPMENT USED IN THE CRUDE OIL DISTILLATION IT IN THE REFINERY.

ASTM test D2892 is used to obtain distillation data out to a maximum of 400 C. This test simulates the atmospheric distillation column but is a batch process unlike the actual column.

ASTM test D5236 is used to obtain distillation data in the 300 - 565 C range. This test simulates the vacuum distillation column but is a batch process unlike the actual column.

The purchase of crude oil is by far the largest cost for any refinery operator. There are many types of crude oil to choose from and most refiners use a blend of crude oils that best matches the configuration of their refinery.

Refineries may be specially designed to process heavy or light crude oils. Some handle high sulfur crude oils and others low sulfur crude oils. Some refineries and researches need more detailed information about the composition of crude oils. In this case they use the Mini and Micro distillation systems to obtain more detailed fractions.

The information can be used for advanced analysis of the crude oil composition. When the data from mini and micro crude oil distillation systems is fed into advanced computer models, engineers can discover better or cheaper crude oil blends to use as feedstock. They can also refine cut points and operating conditions to maximize the most valuable products. Optimized crude oil blending and refinery operations maximizes operating profits.

Our experts related material Contacts – Global Projects and Industry Solutions.